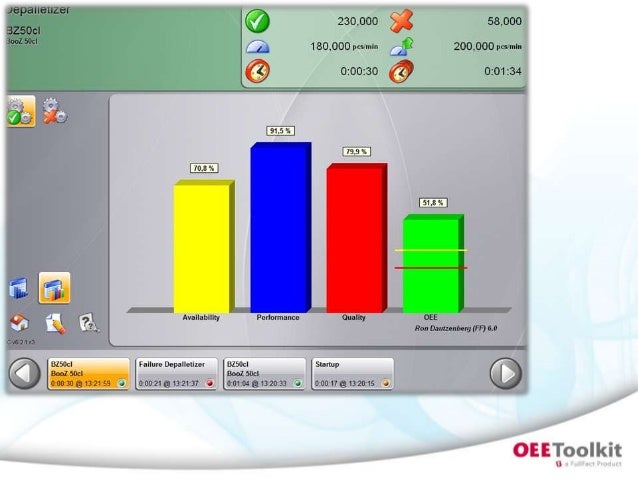

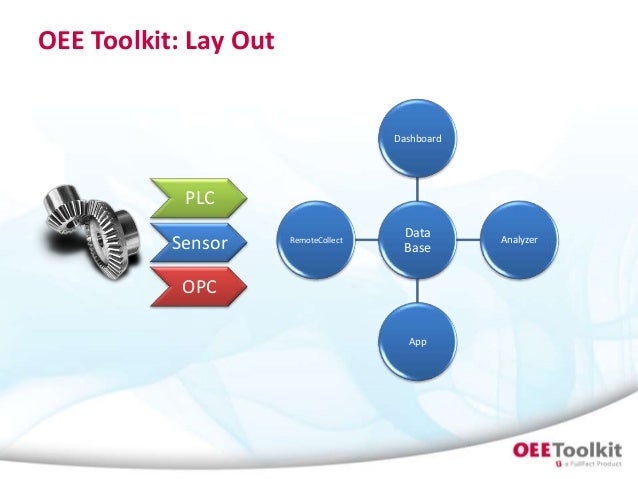

Oee Toolkit

How to Design A Preventive Maintenance Program What is a Preventive Maintenance Plan A preventive maintenance plan attempts to help you proactively perform maintenance, repairs, and replacements so that you can prevent failures before they ever have the chance to occur. A preventive maintenance plan will keep your operation running efficiently, extend the lifetime usage of your assets, and bring your maintenance costs down. Gn 2000 Windows 7 Driver on this page. By designing an effective Preventive Maintenance PM program, organizations can experience substantial improvements in their overall business processes, including increased productivity, decreased waste, improved work execution and reduced unexpected breakdowns. Compare these benefits to the statistics of organizations currently operating in a reactive mode Most maintenance organizations operate between 1. EFA Automazione distribuisce a costruttori di macchine e system integrator soluzioni per la Connettivit e la Comunicazione industriale e supporta architetture IIoT. Windows Xp Sp2 Sata Drivers. Most spend more than 5. Reactive maintenance costs 3 5 times more than preventive maintenance. These metrics can mean falling just short of corporate or production goals and complying with safety regulations or Service Level Agreements. How would your business landscape change if you went from 4. What about 8. 0 What could you do to leverage that boost in productivity

Rockwell Software manufacturing software solutions MES can help you meet your end needs. Find out how you could drive your Continuous Improvement agenda with Idhammar Systems latest OEE System enhancement the Employee Suggestion Scheme module. SecurityStudy. Copyright 2002, 2003 Bredemeyer Consulting 1 Enterprise Architecture as Business Capabilities Architecture Dana Bredemeyer, Ruth Malan, Raj Krishnan and Aaron Lafrenz. What Do World Class PM Programs Look Like World class maintenance programs embrace a proactive approach, in which preventive maintenance represents 6. Effective maintenance programs reflect an organizations future goals, and integrate best practices of planning, implementation and evaluation. PM programs contain planning, scheduling, coordination and reliability support throughout an organization. World class maintenance programs help organizations improve quality, reduce costs, increase equipment uptime, increase Overall Equipment Effectiveness OEE and more. The focus shifts from reacting to problems and a keep it running ideology to performance analysis and continuous process improvement. For example, heres a few client success stories from those who have implemented PM programs Achieved an 8. Downtime Reduction in Six Months. Maintained a 9. 9. Uptime Rate. Maintained 1. Compliance on SLASSo, what goes into designing a Preventive Maintenance programTo help you get started, e. Maint developed six steps to create an effective, world class Preventive Maintenance program. Identify the End Goal The most effective way to begin developing procedures for PM programs is to start with the end in mind. What does your company want to accomplish Define your procedures to align with organizational goals. For example, many manufacturing organizations focus on improving work efficiency. This goal helps guide your processes in order to reap benefits such as reducing equipment downtime, improving work completion rates, and maximizing production time available per machine. Other organizations want to ensure regulatory compliance. With this focus, results such as improved planned maintenance percentage, labor tracking and work history will follow suit. Determine Asset and Equipment Hierarchy Another vital step to developing a PM program is to identify asset equipment lists an inventory of your fixed assets and set up asset hierarchical structures. An asset hierarchy is the relationship between the highest level of equipment and subordinate units, which allows you to easily identify which assets you can perform maintenance on versus all of your tangible pieces, parts andor equipment. Here are a few tips to begin creating an asset hierarchy Again, start with the end in mind. Consider what makes equipment valuable or critical to your organization. What is the total cost of ownership for a particular piece of equipment If this piece of equipment goes down, how is safety impacted Make sure your asset hierarchy is unique. Your hierarchical asset structure should not be cut and pasted from another source. Put a good deal of thought into why it makes sense for your organization. For example, look at a building diagram of your asset domain. What natural groupings do you notice What is the natural geography that drives your decision making Develop parent child relationships for assets. For example, in an equipment hierarchy, a tractor might be classified as two levels above its carburetor system. Rank assets based on criticality. Ranking assets by criticality helps organizations create asset hierarchies. Asset Criticality Ranking is a tool to evaluate how asset failures impact company wide performance and help organizations prioritize work. What equipment failures would have the most detrimental to production, fulfilling customer orders, or safety for your organization Those are your highest ranking assets. Establish Job and Labor Resources. Preventive Maintenance programs, whether written or stored on a Computerized Maintenance Management System, should also include a list of resources necessary to perform work, such as scissors lifts, forklifts, drills, wrenches, etc. A job plan should provide information on job scope, crafts, and hours to allow the supervisor to assign and schedule the correct skills. Crafting job plans will help keep labor organized, controlled and efficient. They offer support to avoid delays and a head start on other job information for the technicians. An effective job plan includes Step by step information on how to complete work. A list of specific tools required to complete work. A list of skills required to complete work. Bill of materials and parts list. Any associated photographs, diagrams, maps, etc. Standard Operating Procedures SOPs necessary to complete work. Any critical safety instructions, lockout tagout procedures, etc. Maintenance planning defines the what and how of labor and materials, and maintenance scheduling encompasses the when and who. Accurate planning and scheduling is the most critical element to ensure a proactive approach to maintenance. In fact, Lifecycle Engineering found that for every hour of effective planning, the typical return is three hours in maintenance labor time saved or an equivalent savings in materials and production downtime. Starting With The Big Picture Long Term Scheduling No matter what you want to accomplish by implementing a PM program, you want as many of your most critical pieces of equipment on a PM schedule as possible. Begin by selecting your first PM candidate using the data from your asset hierarchy and asset criticality rankings. Once that piece of equipment is selected, start with the big picture and create a schedule for the year. List daily, weekly, monthly, quarterly, bi annual and annual tasks based on manufacturer recommendations, history of the asset and input from your operations team. Then, continue this process for all critical assets. The preventive maintenance scheduling software within a CMMS can reduce the amount of manual labor by auto scheduling work orders based on a calendar or meter basis, or use import tools to populate schedules. When you are able to assign work by clicking a button and view all work on a calendar, communication and coordination between schedulers, maintenance crew and managers can be greatly improved. It also helps reduce work backlog because you can adjust work order schedules and assignments when resource and inventory availability changes to reduce the time it takes for work to be completed. Drilling Down Short Term Scheduling With a better understanding of the most critical tasks at hand for the year, establishing weekly maintenance plans for your team will not be as daunting a task.

Rockwell Software manufacturing software solutions MES can help you meet your end needs. Find out how you could drive your Continuous Improvement agenda with Idhammar Systems latest OEE System enhancement the Employee Suggestion Scheme module. SecurityStudy. Copyright 2002, 2003 Bredemeyer Consulting 1 Enterprise Architecture as Business Capabilities Architecture Dana Bredemeyer, Ruth Malan, Raj Krishnan and Aaron Lafrenz. What Do World Class PM Programs Look Like World class maintenance programs embrace a proactive approach, in which preventive maintenance represents 6. Effective maintenance programs reflect an organizations future goals, and integrate best practices of planning, implementation and evaluation. PM programs contain planning, scheduling, coordination and reliability support throughout an organization. World class maintenance programs help organizations improve quality, reduce costs, increase equipment uptime, increase Overall Equipment Effectiveness OEE and more. The focus shifts from reacting to problems and a keep it running ideology to performance analysis and continuous process improvement. For example, heres a few client success stories from those who have implemented PM programs Achieved an 8. Downtime Reduction in Six Months. Maintained a 9. 9. Uptime Rate. Maintained 1. Compliance on SLASSo, what goes into designing a Preventive Maintenance programTo help you get started, e. Maint developed six steps to create an effective, world class Preventive Maintenance program. Identify the End Goal The most effective way to begin developing procedures for PM programs is to start with the end in mind. What does your company want to accomplish Define your procedures to align with organizational goals. For example, many manufacturing organizations focus on improving work efficiency. This goal helps guide your processes in order to reap benefits such as reducing equipment downtime, improving work completion rates, and maximizing production time available per machine. Other organizations want to ensure regulatory compliance. With this focus, results such as improved planned maintenance percentage, labor tracking and work history will follow suit. Determine Asset and Equipment Hierarchy Another vital step to developing a PM program is to identify asset equipment lists an inventory of your fixed assets and set up asset hierarchical structures. An asset hierarchy is the relationship between the highest level of equipment and subordinate units, which allows you to easily identify which assets you can perform maintenance on versus all of your tangible pieces, parts andor equipment. Here are a few tips to begin creating an asset hierarchy Again, start with the end in mind. Consider what makes equipment valuable or critical to your organization. What is the total cost of ownership for a particular piece of equipment If this piece of equipment goes down, how is safety impacted Make sure your asset hierarchy is unique. Your hierarchical asset structure should not be cut and pasted from another source. Put a good deal of thought into why it makes sense for your organization. For example, look at a building diagram of your asset domain. What natural groupings do you notice What is the natural geography that drives your decision making Develop parent child relationships for assets. For example, in an equipment hierarchy, a tractor might be classified as two levels above its carburetor system. Rank assets based on criticality. Ranking assets by criticality helps organizations create asset hierarchies. Asset Criticality Ranking is a tool to evaluate how asset failures impact company wide performance and help organizations prioritize work. What equipment failures would have the most detrimental to production, fulfilling customer orders, or safety for your organization Those are your highest ranking assets. Establish Job and Labor Resources. Preventive Maintenance programs, whether written or stored on a Computerized Maintenance Management System, should also include a list of resources necessary to perform work, such as scissors lifts, forklifts, drills, wrenches, etc. A job plan should provide information on job scope, crafts, and hours to allow the supervisor to assign and schedule the correct skills. Crafting job plans will help keep labor organized, controlled and efficient. They offer support to avoid delays and a head start on other job information for the technicians. An effective job plan includes Step by step information on how to complete work. A list of specific tools required to complete work. A list of skills required to complete work. Bill of materials and parts list. Any associated photographs, diagrams, maps, etc. Standard Operating Procedures SOPs necessary to complete work. Any critical safety instructions, lockout tagout procedures, etc. Maintenance planning defines the what and how of labor and materials, and maintenance scheduling encompasses the when and who. Accurate planning and scheduling is the most critical element to ensure a proactive approach to maintenance. In fact, Lifecycle Engineering found that for every hour of effective planning, the typical return is three hours in maintenance labor time saved or an equivalent savings in materials and production downtime. Starting With The Big Picture Long Term Scheduling No matter what you want to accomplish by implementing a PM program, you want as many of your most critical pieces of equipment on a PM schedule as possible. Begin by selecting your first PM candidate using the data from your asset hierarchy and asset criticality rankings. Once that piece of equipment is selected, start with the big picture and create a schedule for the year. List daily, weekly, monthly, quarterly, bi annual and annual tasks based on manufacturer recommendations, history of the asset and input from your operations team. Then, continue this process for all critical assets. The preventive maintenance scheduling software within a CMMS can reduce the amount of manual labor by auto scheduling work orders based on a calendar or meter basis, or use import tools to populate schedules. When you are able to assign work by clicking a button and view all work on a calendar, communication and coordination between schedulers, maintenance crew and managers can be greatly improved. It also helps reduce work backlog because you can adjust work order schedules and assignments when resource and inventory availability changes to reduce the time it takes for work to be completed. Drilling Down Short Term Scheduling With a better understanding of the most critical tasks at hand for the year, establishing weekly maintenance plans for your team will not be as daunting a task.